At PROTEC we deliver precision CNC tapping services in steel and aluminium, ensuring repeatable internal threads, short cycle times and outstanding quality for both series and small batches. As a full-service metal components manufacturer, we integrate tapping with stamping, cutting, bending and assembly to streamline your supply chain.

Scope of Service

Our CNC tapping capabilities cover internal threads in carbon steel, stainless steel and aluminium with controlled tolerances and high repeatability. We produce threads according to your drawing in metric sizes – both through-holes and blind holes – tailored for construction, renewable energy, industrial and OEM applications.

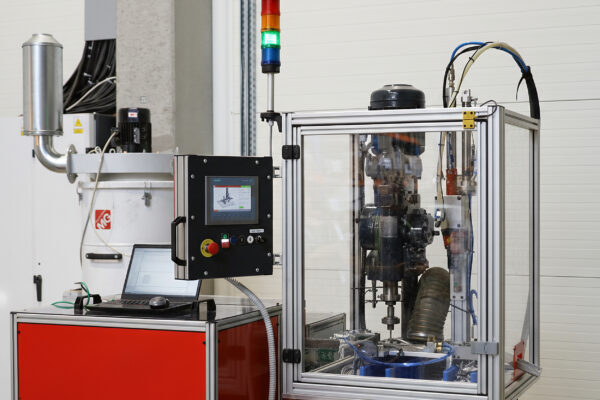

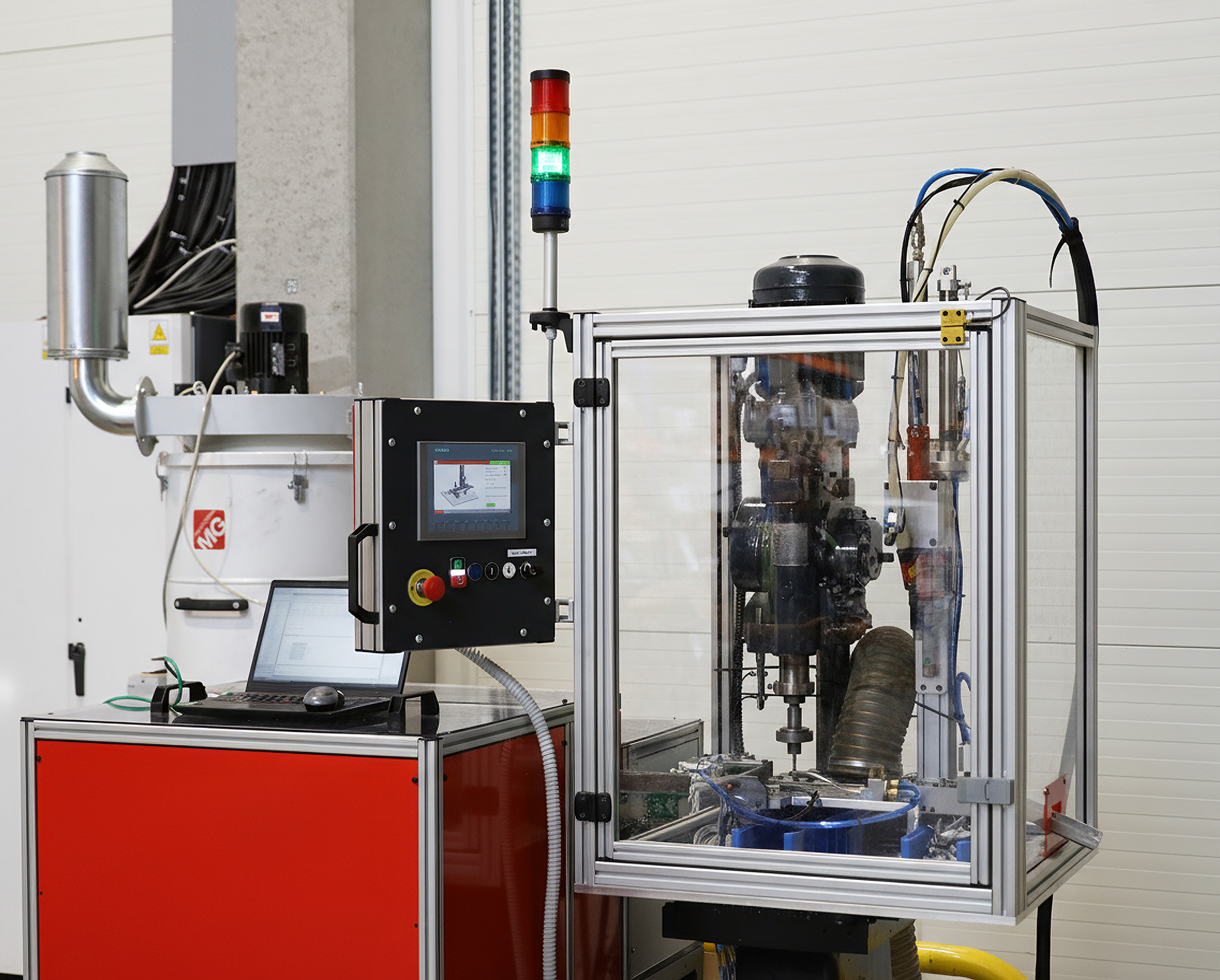

Automated Tapping Stations – Stable Quality

Our automated tapping stations offer fast cycle times, programmable direction and speed settings, integrated lubrication and inline chip removal for a clean thread profile free of burrs. Quick changeovers allow efficient production of small batches and series alike.

Materials, Tolerances and Thread Parameters

We work with carbon steel, stainless steel and aluminium, paying special attention to edge quality and load-bearing core diameter. Tool geometry, cooling and cutting parameters are matched to material, thread diameter and pitch to achieve the required tolerance and thread fit.

- Pre-drilled hole diameter and thread depth controlled according to drawing and standards.

- Support for blind and through-holes with measurement protocols and documentation on request.

Quality Control & Documentation

Every batch is subject to inspection of thread profile and depth using gauges and visual checks. Burrs and chips are removed at source so that components are ready for coating or assembly. We supply batch documentation and verification of key parameters upon request.

Industries & Who Benefits

This service is ideal for manufacturers of metal components requiring consistent thread quality – such as stamped brackets, plates, profiles and machined parts. Integrators, contractors in construction and renewable energy installations will also benefit from our integrated manufacturing flow.

The service is also suitable for integrators and contractors of structures with screw-mounted elements in construction, OZE installations and industrial equipment. Combining tapping with other metalworking operations at PROTEC helps these companies keep short delivery times and predictable costs.

Key Benefits of CNC Tapping at PROTEC

- Shorter cycle times and fewer operations thanks to automated tapping stations.

- Repeatable thread quality with precise depth control in blind and through-holes.

- Full integration with cutting, bending, stamping and assembly at PROTEC – reducing logistics effort and machine changeovers.

Parameters & Capabilities

We cover most industrial thread sizes on both through and blind holes per 2D drawing or 3D model, in stamped, laser-cut or machined parts. We support new project small batches as well as full-scale serial production with documentation and agreed control plans.

Ready to Get Started?

If you are looking for a supplier that can combine CNC tapping with stamping, cutting and assembly in one production flow - contact PROTEC today. Share your drawings and we will provide a quote for series or small-batch production of metal components.

Contact Us