Robotic Welding at PROTEC

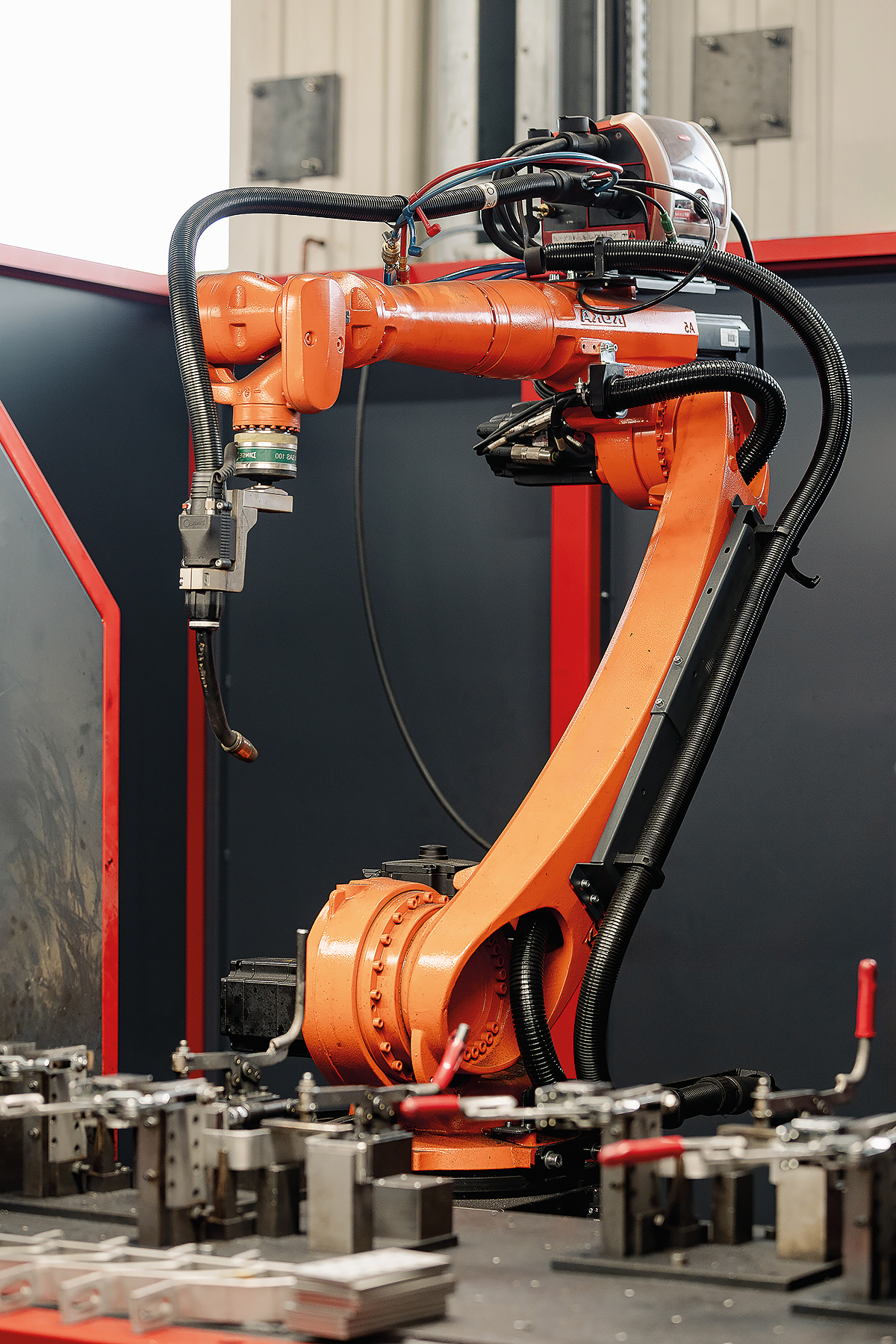

Robotic Welding at PROTEC delivers consistent weld quality and cycle-time efficiency for steel, stainless steel and aluminum parts in both series and mass production.

Supported by welding robots for high repeatability and clean seams, our process ensures precision and reliability.

Integrated within broader Metalworking, the welding stage connects CNC machining, stamping, laser cutting, bending and final assembly – providing end-to-end production from prototype to finished goods.