At PROTEC, the most important thing is to comply with an established Quality Policy that ensures always tested, aesthetic and solid products are produced.

Certified quality of products and services

Our production is based on individual customer requirements in accordance with normative technical and quality standards. We deliver prototypes, initial samples, individual production and batch production - always with full quality control.

Highest standards for your project

By maintaining the highest quality standards, we offer manufacturing of elements that meet the expectations of our customers and delivery of orders within the agreed timeframe. We require our suppliers to provide deliveries that fully meet our requirements and those of our customers.

Quality management system based on the requirements of standards

PROTEC quality policy is based on an implemented and continuously improved Integrated Management System that meets the requirements of the following international standards:

ISO 9001:2015 - quality management system

ISO 14001:2015 - environmental management system

ISO 45001:2018 - occupational health and safety management system

VDA 6.3 - quality standard for the automotive industry

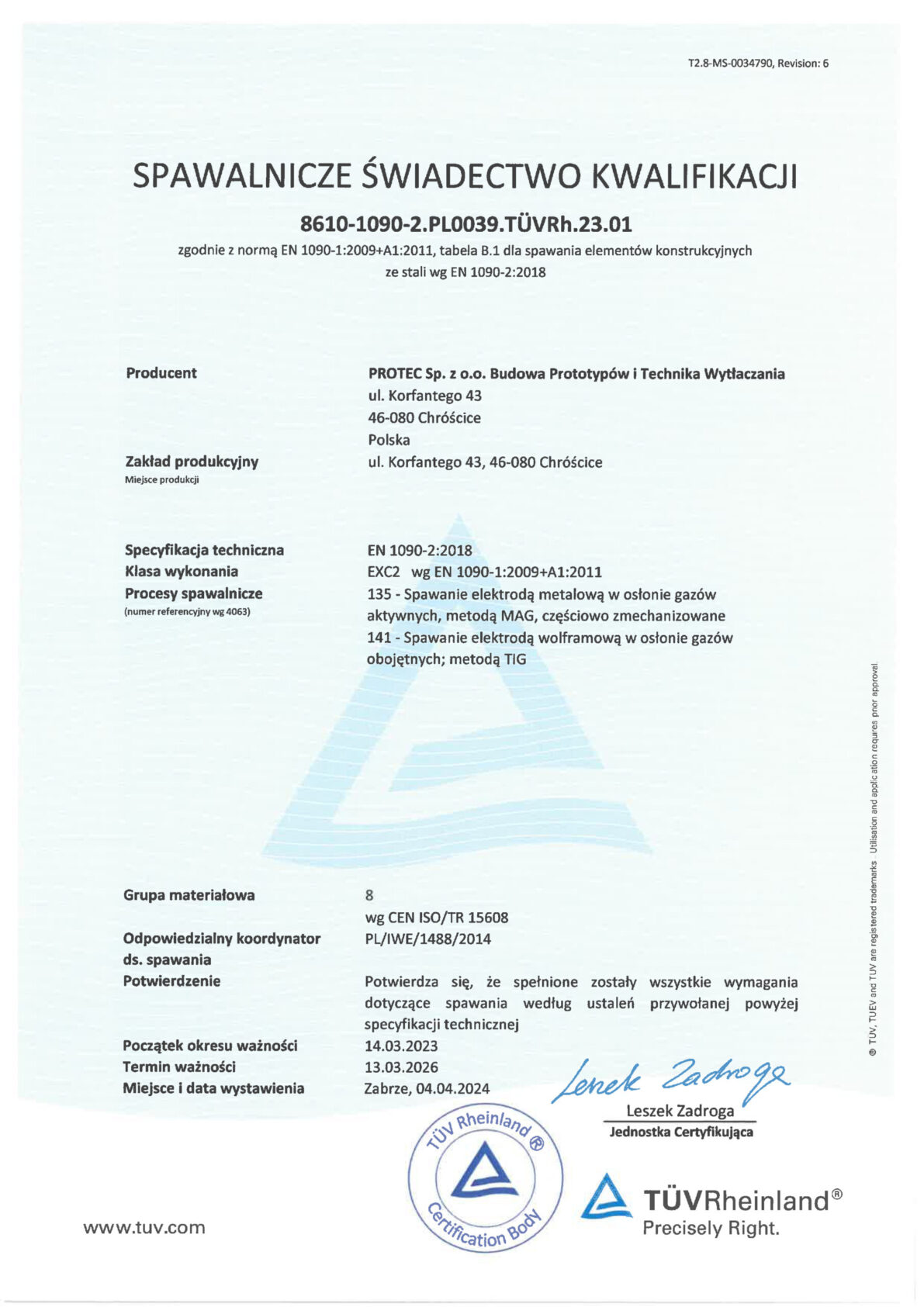

EN ISO 3834-2 - quality of MAG and TIG welding processes

EN 1090-2 - structural elements made of steel and aluminium with CE marking

Why choose PROTEC?

Globally recognized certificates

We meet the requirements of the automotive, structural and industrial sectors

Full traceability

Every product can be tracked from raw material to finished product

Technical support

Advice from prototype to batch production

Audits and continuous improvement

We regularly verify and improve our processes

PROTEC Integrated Management System

Policy Sp. z o.o.

Quality, Environmental Protection, Health and Safety Management Policy is a fundamental element of PROTEC’s operations. It is a key tool in carrying out the production of products for clients in the areas of stamping, bending, profiling, and welding of mounting and fastening elements for photovoltaic and installation systems, as well as cutting, processing, packaging, and manufacturing elements of the roof drainage system from various types of steel and non-ferrous metals. These main areas are complemented by auxiliary processes such as assembly, packaging, corrosion protection, and comprehensive logistics.

We conduct our operations based on the principle of sustainable development, which assumes conscious and interdependent relationships between economic growth, environmental protection, and at the same time, care for the satisfaction and health of people, i.e., our employees, neighbors, and clients.

PROTEC is committed to:

-

Fulfilling orders and delivering products of the highest quality, in accordance with customer requirements,

-

Continuously improving the Integrated Management System in accordance with the requirements of quality, health and safety, and environmental standards,

-

Taking actions to eliminate hazards and reduce risks related to health and safety, as well as environmental protection, and ensuring full compliance with legal requirements,

-

Improving processes by applying a risk-based approach and utilizing emerging opportunities, including raising the quality and efficiency of technological processes through the implementation of innovative solutions,

-

Systematically developing and improving relationships with stakeholders, including enabling employees to participate in consultations regarding the provision of safe and hygienic working conditions,

-

Preventing and minimizing the negative environmental impact by identifying, monitoring environmental aspects, and taking initiatives for environmental protection, considering the production processes of products.

In our efforts to achieve set goals, we are always guided by the motto “zero defects – zero flaws,” ensuring that the customer receives a product that meets their expectations.

To achieve these goals, the Management of Protec Sp. z o.o. commits to:

-

Complying with applicable legal and environmental requirements,

-

Raising employees’ awareness of the importance of meeting customer requirements, legal requirements, and the values in force within the company,

-

Creating conditions for employee involvement in achieving goals and systematically raising qualifications,

-

Conducting business in an environmentally friendly manner, ensuring the health and safety of employees,

-

Providing all necessary resources to achieve set goals and commitments,

-

Supporting good practices and promoting values, attitudes, and behaviors that prioritize environmental protection and health and safety issues.

The effectiveness of this Policy is guaranteed by the widespread awareness that the responsibility for the highest quality, environmental protection, and health and safety at work lies with every employee of Protec, which is why all employees and management are committed to adhering to it and continuously improving the assumptions of the Integrated Management System.

Chróścice, October 2, 2024 r.