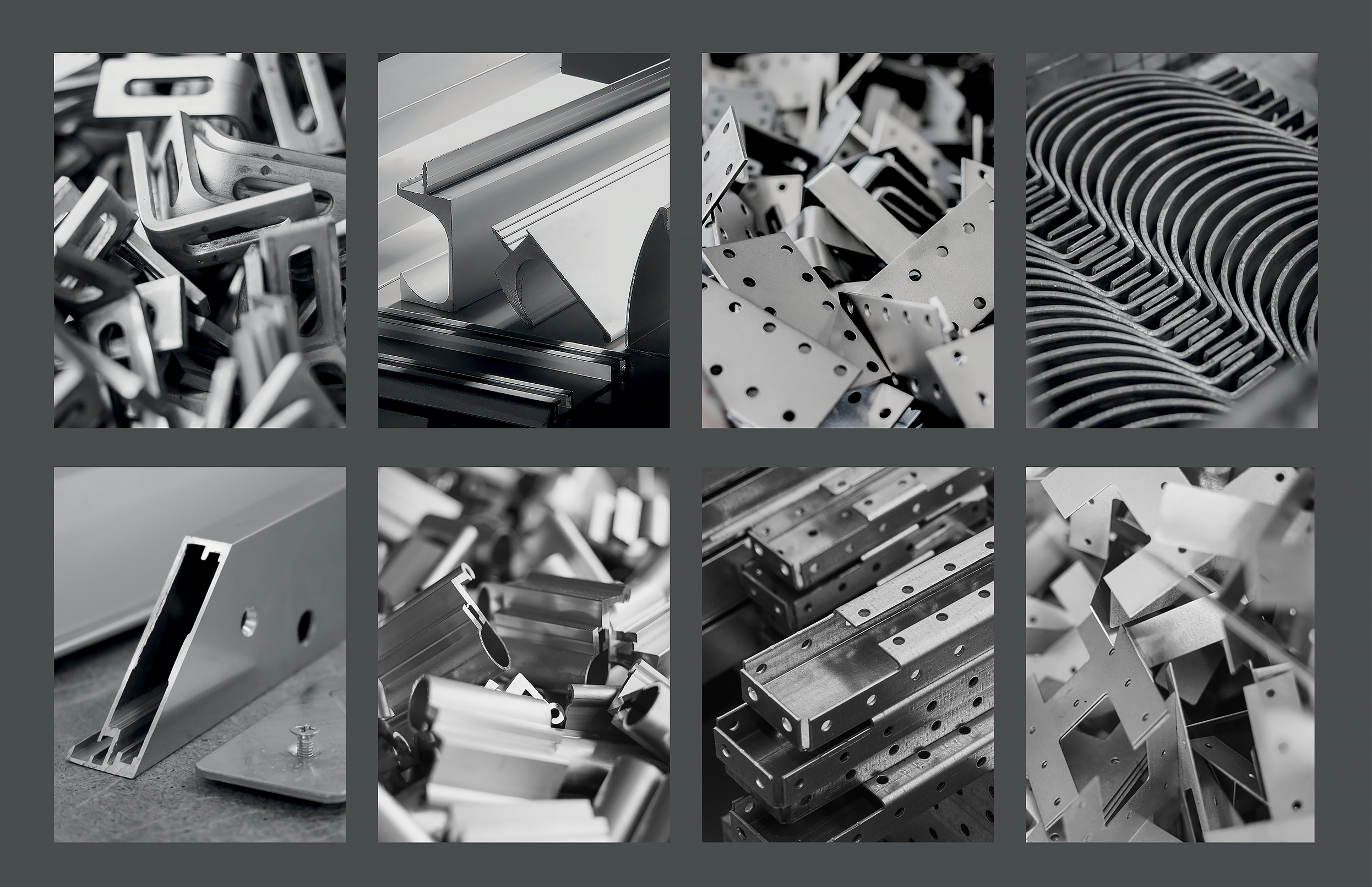

Comprehensive OEM Production

Solutions for Your Brand

At Protec Sp. z o.o., we provide comprehensive Original Equipment Manufacturer (OEM) solutions, enabling our partners to bring high-quality products to market under their own brand—without the need to invest in complex production facilities or processes.

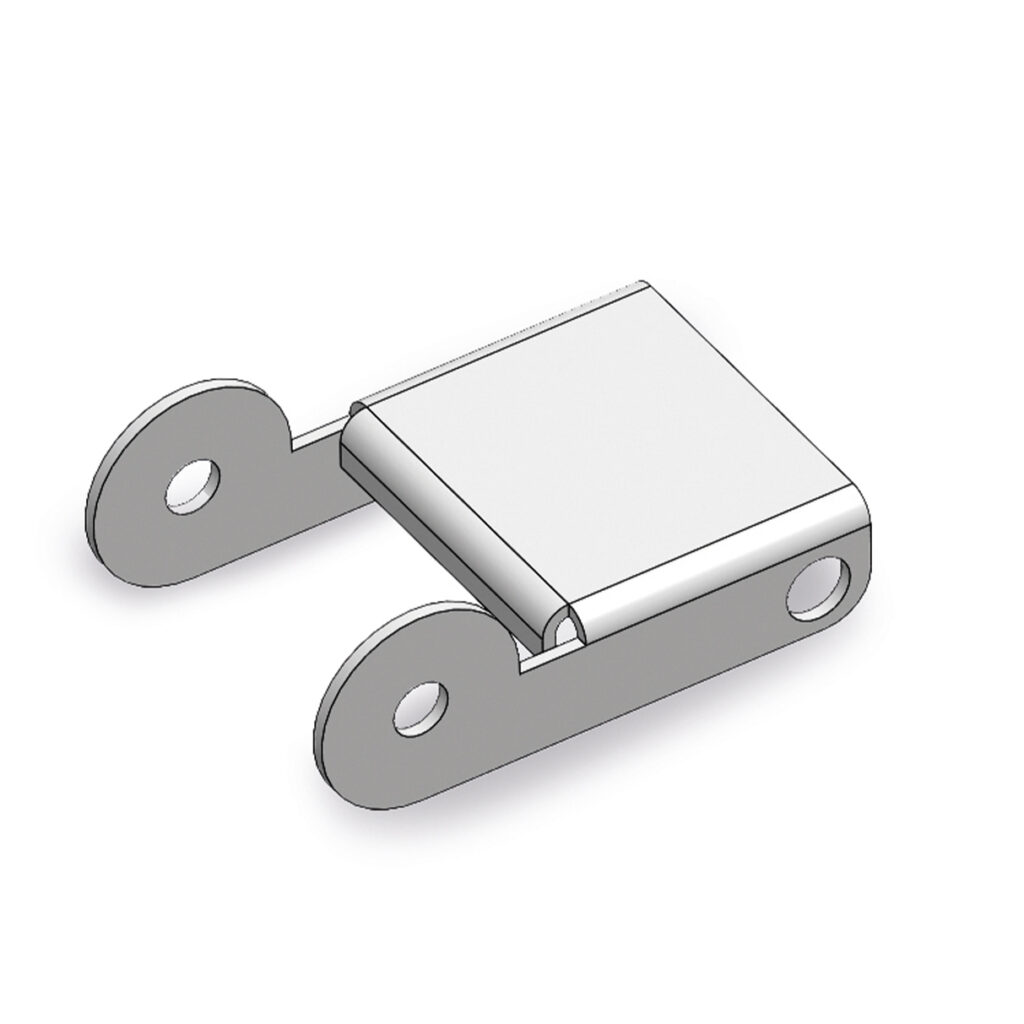

With our extensive industry expertise, advanced manufacturing technologies, and commitment to excellence, we take full responsibility for every stage of production—from concept design to the finished product.