Production under the client's brand

Order Placement Process

01. Inquiry

Send us a drawing or a pattern of your product, present your requirements and we will prepare an individual offer for you.

02. Production

We will make your product in accordance with your expectations and applicable production standards.

03. Satisfaction

Please send us a drawing or sample of your product, outline your requirements, and we will prepare a customized offer for you.

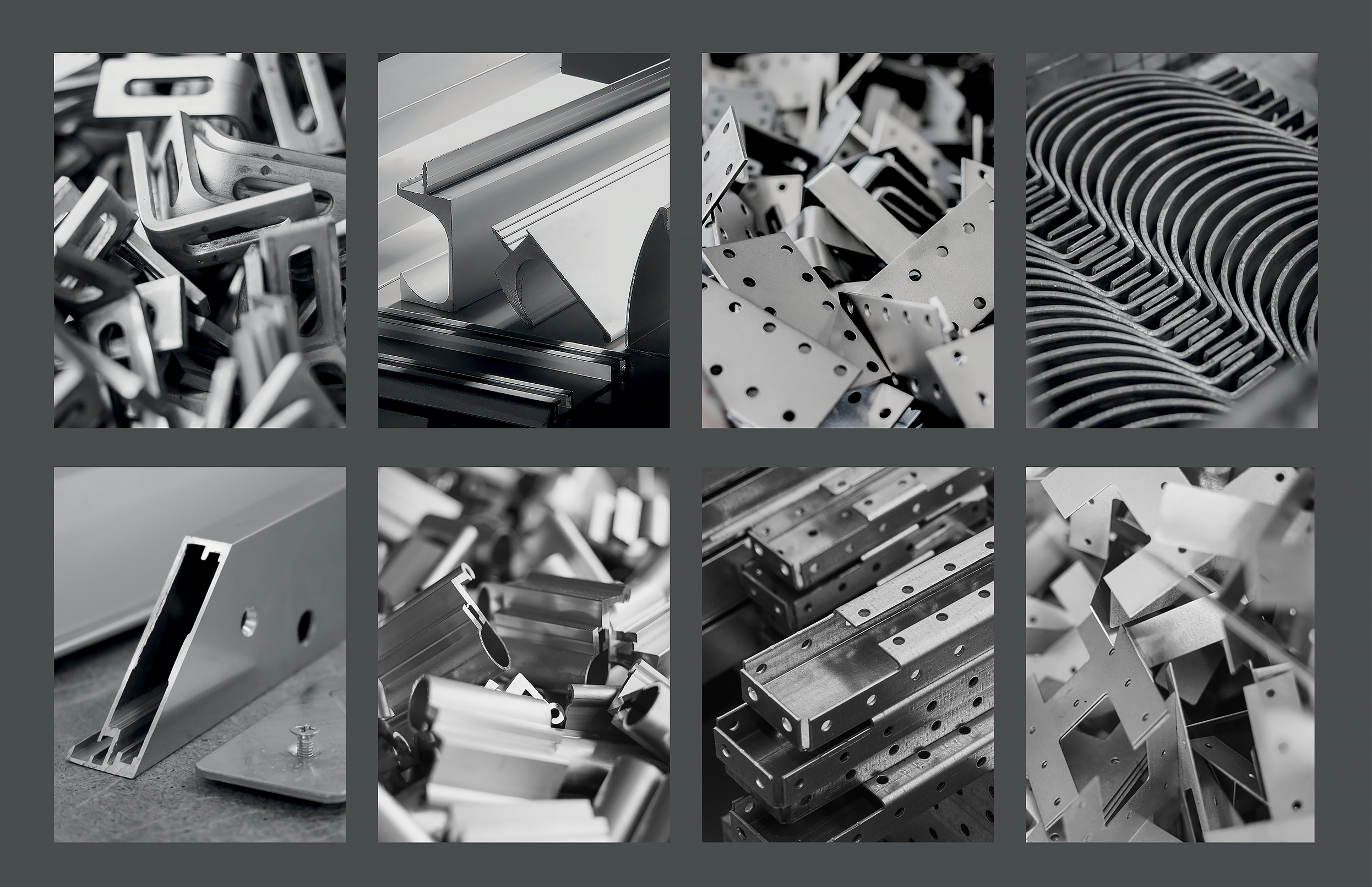

What do we offer?

We offer comprehensive production services under the client’s brand, ensuring the production of high-quality products without the need to engage in the entire technological and production process. Thanks to our experience and modern technological solutions, we can take full responsibility for production, from concept to finished product.

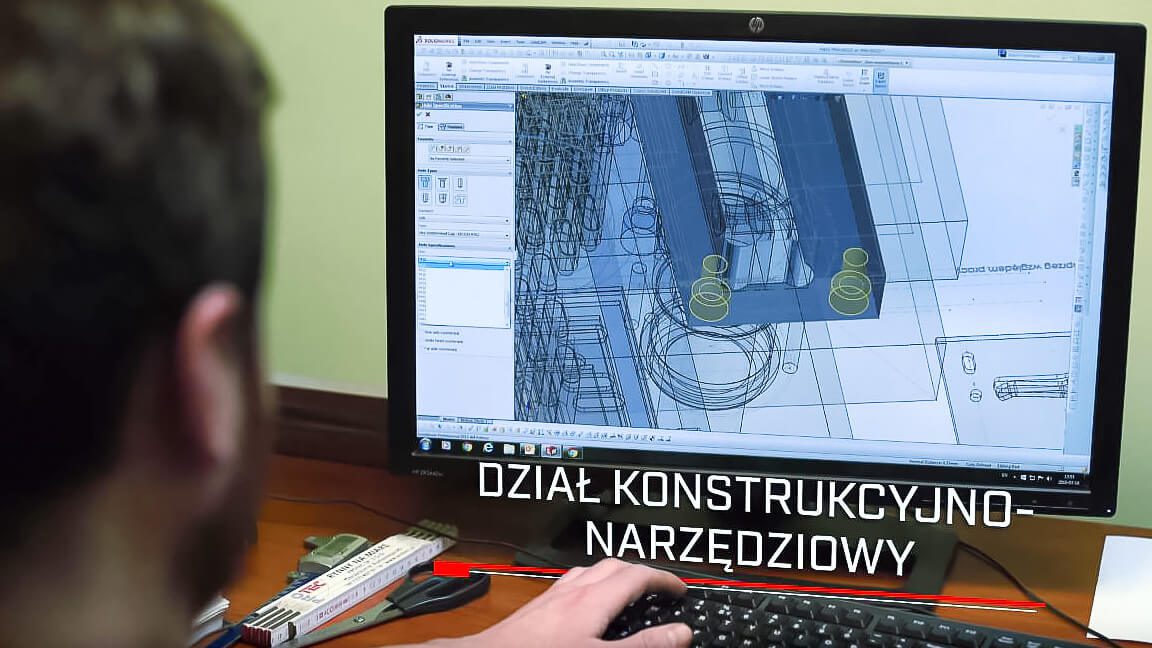

Prototype and Tool Development

As part of our collaboration on the Client’s project, we offer support in various areas of product development.

We create prototypes of new products and components in accordance with the Client’s technical documentation, ensuring the highest quality of execution and compliance with requirements.

We design and manufacture tools, such as punches, dies, and multi-stroke cutting tools, essential for efficient production.

Production and quality control

Our production equipment mainly consists of numerically controlled metalworking machines, CNC bending machines, eccentric and hydraulic presses, and robotic centers. We have a fully automated line for the production of various shaped products. This line integrates the processes of straightening, punching, cutting, multi-axis bending, and both simple and shaped cutting. Monitoring for consistency and efficiency operates fully on telemetry and is controlled through the MES and ERP abas systems.

In all areas of our operations, we continuously strive for improvement to ensure that all customer requirements, legal regulations, and our internal procedures are met. These procedures are based on our Integrated Quality and Environmental Management System, which complies with international standards ISO 9001:2015 and ISO 14001:2015. Additionally, our certified Factory Production Control ensures compliance with the highest quality standards according to EN 1090 and ISO 3834.

Warehousing, logistics and distribution

Advanced warehouse management systems enable real-time inventory monitoring, allowing for continuous control and optimization of warehouse processes.

With our own fleet of vehicles and close cooperation with freight forwarders, we guarantee efficient distribution of products to any location worldwide.

Certified quality of products and services

Quality management system

Want to start cooperation? Contact us at: sprzedaz@protec.pl

Our Projects

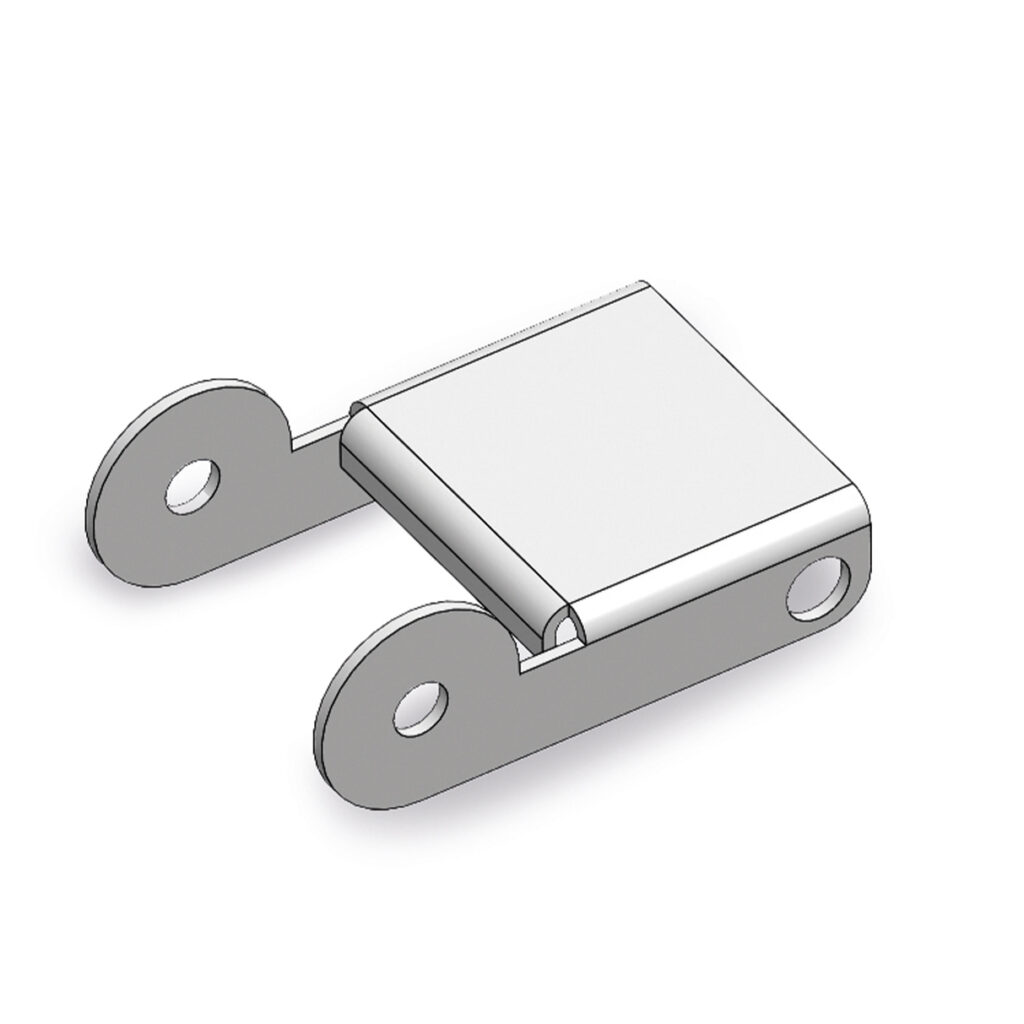

Projects that we perform in cooperation with contractors. We treat each project individually, adapting our services to the specific needs and expectations of our business partners.

Explore our other services

We specialize in the precision processing of materials such as steel, stainless steel, and aluminum.